SIGNIFICANT FINANCIAL & ENVIRONMENTAL BENEFITS OF INDUSTRIAL HEAT RECOVERY APPLICATIONS:

DDFC waste heat recovery systems for exhaust stream temperatures of up to 1000°C are the best choice for any Industry. For higher temperatures, specialized and more sophisticated designs are also available. Waste heat systems make possible the recovery of heat being discharged into the atmosphere as supplemental energy for another process. As energy costs rise, the demand for more efficient and cost effective energy utilization increases.

DDFC waste heat recovery systems for exhaust stream temperatures of up to 1000°C are the best choice for any Industry. For higher temperatures, specialized and more sophisticated designs are also available. Waste heat systems make possible the recovery of heat being discharged into the atmosphere as supplemental energy for another process. As energy costs rise, the demand for more efficient and cost effective energy utilization increases.

DDFC proudly presents its experience in products and services, gathered in this field over two and half decades and provides an extensive portfolio of customized and standardized solutions for waste heat recovery to ensure long-term optimization of plant performance, quality, and productivity. Each waste heat recovery system is custom engineered for a specific requirement.

DDFC proudly presents its experience in products and services, gathered in this field over two and half decades and provides an extensive portfolio of customized and standardized solutions for waste heat recovery to ensure long-term optimization of plant performance, quality, and productivity. Each waste heat recovery system is custom engineered for a specific requirement.

Multi-Generation Systems:

Multi-Generation Systems:

DDFC specializes in heat recovery from internal combustion (I/C) engines. Steam or hot water can be produced by utilizing energy in the exhaust. This steam / hot water is used in the process or to run an absorption chiller for producing chilled water. Similarly heat energy in the engine jacket, lube oil system can be recovered in the form

of hot water for process use or operating absorption chillers. Therefore with one input three outputs viz, electricity, steam and hot water are generated which is appropriately known as Tri-generation system.

of hot water for process use or operating absorption chillers. Therefore with one input three outputs viz, electricity, steam and hot water are generated which is appropriately known as Tri-generation system.

· Heat Recovery from Gas Turbine exhaust provides large quantity of process steam or high pressure steam for running steam turbine for further power generation.

· Industries using thermal oil heating systems can generate hot water from exhaust of these

heaters.

High Return on Investment:

Waste Heat Recovery Boilers present an ideal opportunity for investment since the payback period is quite attractive being less than one year if process steam is produced and utilized round the clock.

OVERVIEW

DDFC (Pvt.) Ltd. is one of the leading Engineering & Fabrication companies in Pakistan, manufacturing Steam Boilers & Waste Heat Recovery Boilers to British Standard BS 2790. The boiler designs were initially provided by M/s Beel Industrial Boilers Plc, UK, our licensor for 14 years. Waste Heat Recovery Boilers (WHRBs) are used to convert heat in the exhaust gases from diesel, heavy fuel oil and natural gas fired engines or turbines into useful products such as steam or hot water and consequently reduce heat emission into the atmosphere.

DDFC (Pvt.) Ltd. is one of the leading Engineering & Fabrication companies in Pakistan, manufacturing Steam Boilers & Waste Heat Recovery Boilers to British Standard BS 2790. The boiler designs were initially provided by M/s Beel Industrial Boilers Plc, UK, our licensor for 14 years. Waste Heat Recovery Boilers (WHRBs) are used to convert heat in the exhaust gases from diesel, heavy fuel oil and natural gas fired engines or turbines into useful products such as steam or hot water and consequently reduce heat emission into the atmosphere.

WHRBs are also used for recovery of waste heat generated from process in refineries, fertilizer and

sponge iron plants where the high pressure steam produced runs steam turbines for power

generation.

DDFC manufacturers Smoke Tube type WHRBs in various capacities & pressure ratings:

Capacity:

The capacity of a Waste Heat Recovery System/Boiler is dependent upon the mass flow rate and temperature of the available exhaust gases. Multiple engines can be connected to a single WHRB, therefore we have connected 4~5 engines to a single WRHB i.e. Quaduplex and Pentax configuration.

Pressure Rating:

Up to 25 bars(g).(Depending on size)

Design Verification & Third Party Insurance:

DDFC boiler design is verified by a UK based consultant. The final design is also checked & verified by Royal Sun Alliance Insurance Co.

of UK, if so desired by the customer.

Single and Two Pass Designs:

DDFC offers the two pass design to customers with limited footprint requirements. Space permitting, a single pass design is preferred since

it produces lesser back pressure on the prime mover.

SALIENT FEATURES:

Customized Solutions:

Each DDFC Waste Heat Recovery Boiler is specifically engineered & built to the customer’s needs & specifications. Special features & auxiliary equipment are provided as required by the customer.

Raw material & components:

Certified materials and components Certified materials and componentsare procured from leading manufacturers to ensure quality, reliability & trouble free operation.

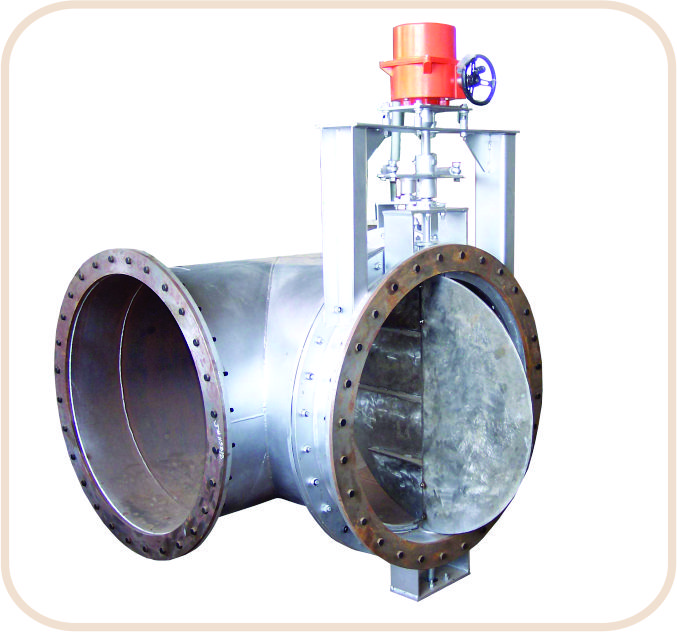

Damper for Exhaust Gas Flow Control:

The pressure in WHRB is controlled through a damper which allows the exhaust gases to pass through the boiler or vent to the atmosphere.

Dampers are generally ON/OFF type for most duties. Modulating dampers are available for special applications requiring minimum variation in pressure e.g. steam turbines. Dampers are electric motor actuated with provision for manual operation. Pneumatic actuators can also be supplied on request.

Ease of Smoke Side Inspection:

Hinged bolted doors provide full access to smoke side tube surfaces for inspection and cleaning on one side of WHRB. The smoke box on other side is equipped with large removable covers for entry purpose.

Instrumentation & Control:

Each WHRB is provided with an Each WHRB is provided with an electric control panel, which is either floor or wall mounted for indoor application. It houses all boiler controls, electrics, and mainisolating switches. The control panel also displays various boiler parameters and alarms. PLC basedcontrol systems are also availableon request.

Capacity Enhancement through Supplementary Firing System:

Exhaust from turbines containing more than 10% oxygen can be utilized by supplementary fired burner to further heat the exhaust gases which increases the steam output capacity of the WHRB.

Special burners suitable for I/C engine exhaust containing 4-6% oxygen can also be provided.

Power Generation Through Waste Heat Recovery:

If engine based power plant has a working capacity of 8MW or more, then an economic solution for power generation through production of super heated steam and a steam turbine generator set is feasible.

DDFC has proven track record in this field.

ANCILLARY EQUIPMENT:

The following ancillary equipment is offered for the complete package.

The following ancillary equipment is offered for the complete package.

- Feed water tank with dearator for non-pressurized systems. It is equipped with heating coils, spargers, temperature control system.The same system can be offered in a pressurized tank configuration as well.

- Feed Water Pumping system with operational/standby pumps. It is normally provided with necessary valves & controls.

- Economizers help improve efficiency by increasing temperature of feed water by capturing additional heat from the exhaust gases in the stack. This increases the steam output of the WHRB. Depending upon location & application, WHRBs can be provided with independent or combined economizers.

- Measuring Instruments for steam and water can be provided on request for local or remote application. PLC based systems are also available.

THE DDFC ADVANTAGE

DDFC offers the following advantages to ensure high standards of customer satisfactions:

Warranty:

DDFC provides warranty against defects of design, material and workmanship for a specified period.

Quality Assurance:

DDFC’s quality management systems are certified to ISO 9001-2008 by Lloyd’s Register of Quality Assurance the world’s most respected institution in this field. It is an assurance to our customers that our quality standards are universally acceptable and at par with the international organizations.

After Sales Service:

DDFC’s skilled personnel ensure prompt DDFC’s skilled personnel ensure prompt response to customer needs.

DDFC offers complete turnkey services i.e. from concept to commissioning for a complete steam generation system including detailed engineering of steam distribution network.

Proven Track Record

DDFC is proud to have manufactured, installed and commissioned Waste Heat Recovery Boilers for National and Multinational companies in the following industries:

· Textile

· Power Generation

· Steel

· Chemicals

· Dairy & Food

· Pulp & Paper

DDFC is also proud to have exported Waste Heat Recovery Boilers.