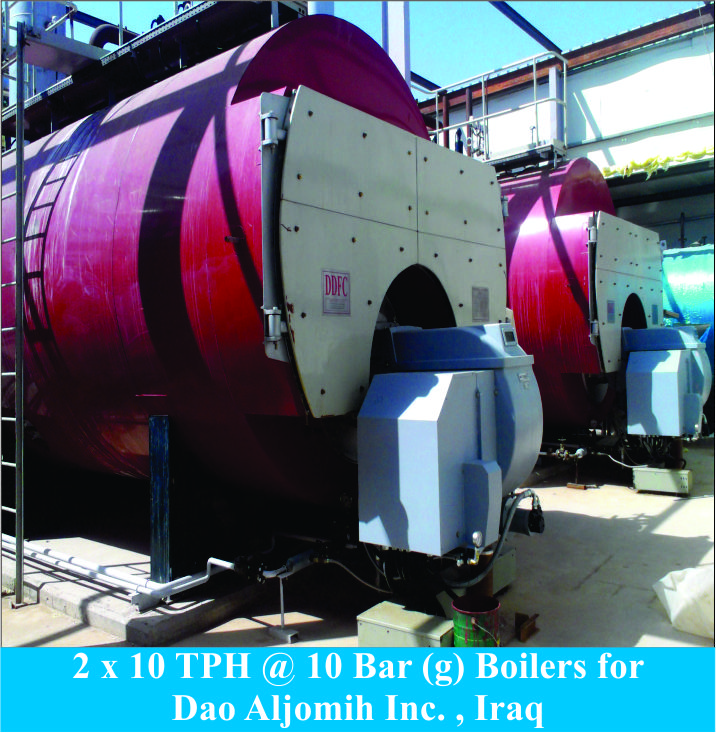

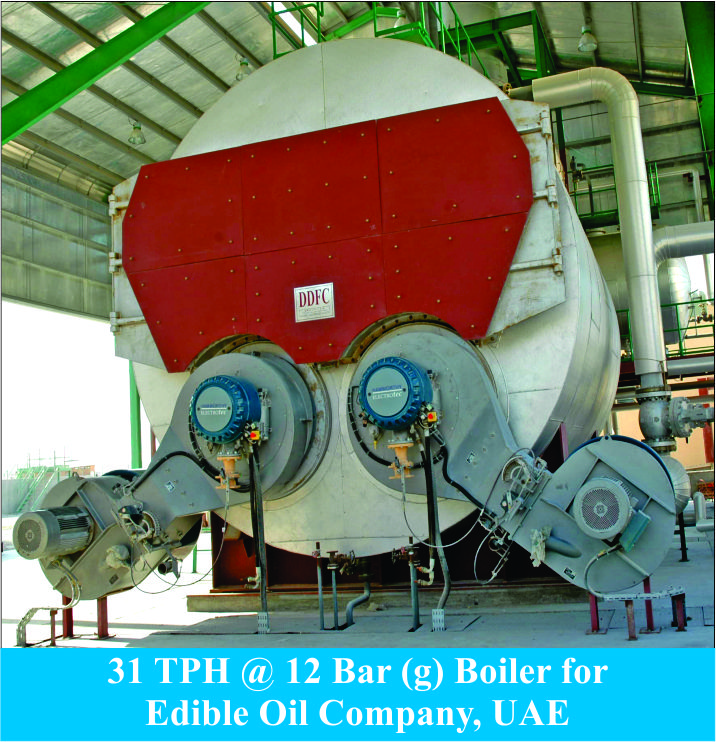

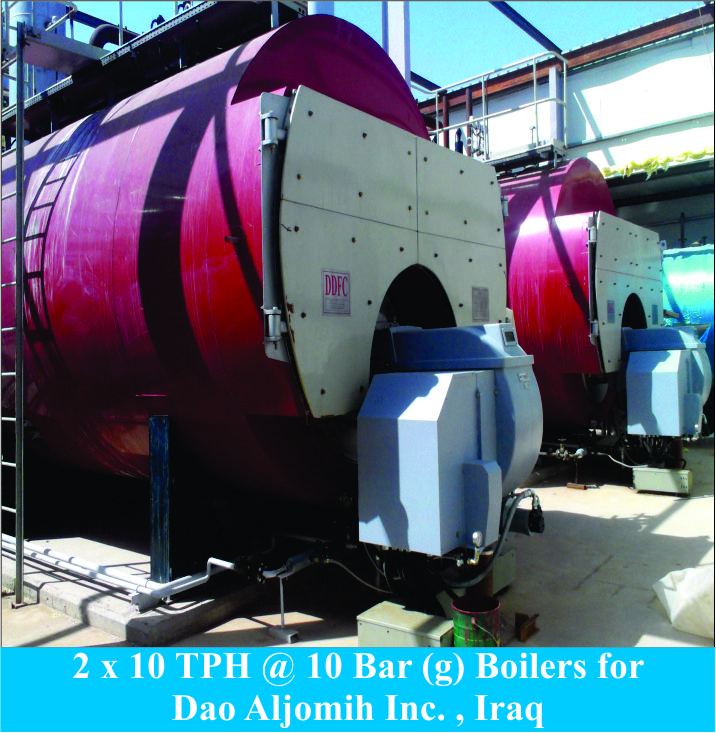

DDFC (Pvt.) Ltd.

is amongst the leading engineering & fabrication companies manufacturing steam boilers to British standards BS 2790 latest addendum . DDFC manufactures smoke tube boilers in the following capacities and pressure ratings.

Capacity :

2 tons per hour to 32 tons per hour. Capacities beyond 20 TPH utilize twinfurnace design.

Pressure Rating :

Upto 25 bars (depending upon capacity)

Design Verfication

DDFC designs its boilers which are verified by a UK based consultant. The final design is checked and approved by Royal Sun Alliance Insurance Co. Of UK, when required.

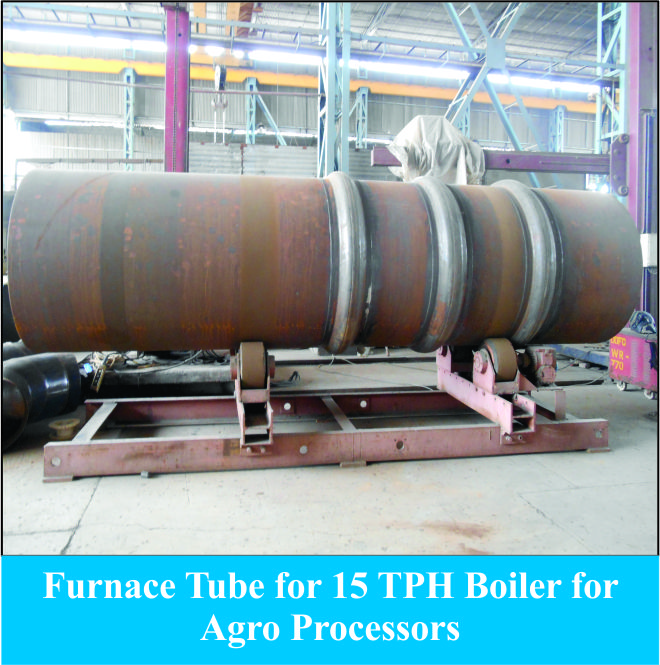

3 Pass Wet Back Design

Proven and time tested 3 pass wet backdesign with full submerged reversal chamber is considered the work horseof the industry.

1- European design

2- Maximum Efficiency

3- Minimum Maintenance

4- Multi fuel firing

5- Quality assured

6- Enabled full customization

Custom Engineered &Manufactured

Every DDFC boiler is specifically engineered and built to the customer’sneeds & specifications. Special features, fuel and auxiliary equipmentare provided according to requirements.

No Proprietary Components

The majority of DDFC boiler controls orinstrumentation are “off the shelf” itemsfrom internationalmanufacturers whicheliminates stocking of proprietary partsand lengthy down time in the event ofcontrol malfunction.

The boiler is provided with an electriccontrol panel that houses all boilercontrols, burner control, equipmentstarters, circuit breakers and mainisolating switch. The panel is powdercoated steelconstructed to Ip42standard. Higher enclosure ratings arealso available. PLC based controlsystem is also available as an option.

Ease of Fire Side Inspection

Front & rear doors are hinged to providefull access to fire side tube surfaces,which eliminates the necessity ofdisconnecting the burner and fuel piping.

Ease of Water Side Inspection

Man hole on top of the shell andsedimentation holes on the shell’s lowerpart provide easy access for inspectionof water side surface.

Blow Down

Each boiler is equipped with aconnection where a manual orautomatic Blowdown system can be

installed for maintaining propre TDS inthe boiler water.

Raw Materials & Components

Certified raw materials and componentsare procured from leading international manufacturers to ensure quality,reliability and trouble free operation.

Combustion Systems

DDFC provides a wide range of single ordual fuel burners in nozzle or rotary cup designs to satisfy customer needs andbudgets. Low NOx&SOx burners forstringent environmental requirementsare also available.

DDFC supplied combustion system forlarge boilers can be fitted with an oxygentrim system which reduces the excessair in the exhaust gases thus reducingheat losses and improving fuel efficiency.

Ancillary Equipment

The following ancillary equipment isoffered for the complete package. Thecustomer has the option to furnish theseitems himself which do not adverselyaffect the performance or the warrantyof equipment.

- Feed water tank with deaeratorhead for non pressurized system.The feed water tank is equipped withheating coils, spargers, temperaturecontrol system and optional levelcontrol probes. The same systemCan be offered in pressurized tankconfiguration as well.

- Feed water pumping system withone operation & one stand by pumpis normally provided along withnecessary valves & controls.

- Fuel oil storage & pumping systemfor heavy fuel oil/diesel oil can bedesigned & provided uponcustomer’s request.

- Economizers help improve thermalefficiency by capturing additionalheat form exhaust gasses usingthemto heat feed water. This in turnreduces fuel consumption of theboiler. These units are offered as astandard with all natural gas firedboilers with capacity of 2 TPH orlarger. These are available for HFOfired boiler.

- Measuring instruments for steam,water, fuel oil can be provided onrequest for local or remoteapplication. PLC based system arealso available.

DDFC offers the following advantages to ensure high standards of customer satisfaction.

Warranty

DDFC provide warranty against defects of design, material and workmanship for a specified period.

Quality Assurance

DDFC quality management systems are certified to ISO 9001:2008 by Lloyd’s Register of Quality Assurance, the world’smost respected institution in this field. It is an assurance to our customers that our quality standards are universallyacceptable and at par with the international organizations.

After Sales Service

DDFC’s skilled personal ensure prompt responses to customer need.

Turnkey Service

DDFC offer complete turnkey service i.e from concept to commissioning for a complete steam generation systemincluding detailed engineering of steam distribution network.

Proven Track Record

DDFC is proud to have manufactured installed and commissioned steam boilers for national and multi national companies inthe following industries.

Textiles! Power Generation ! Chemicals ! Petrochemicals ! Pharmaceuticals ! Cement ! Food & Dairy